| Equipment: |

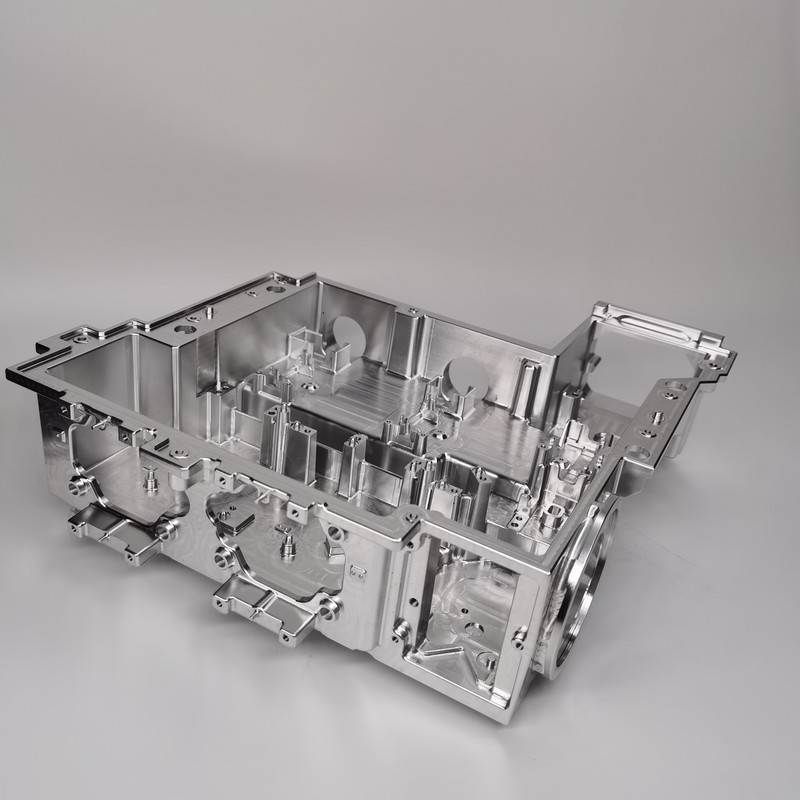

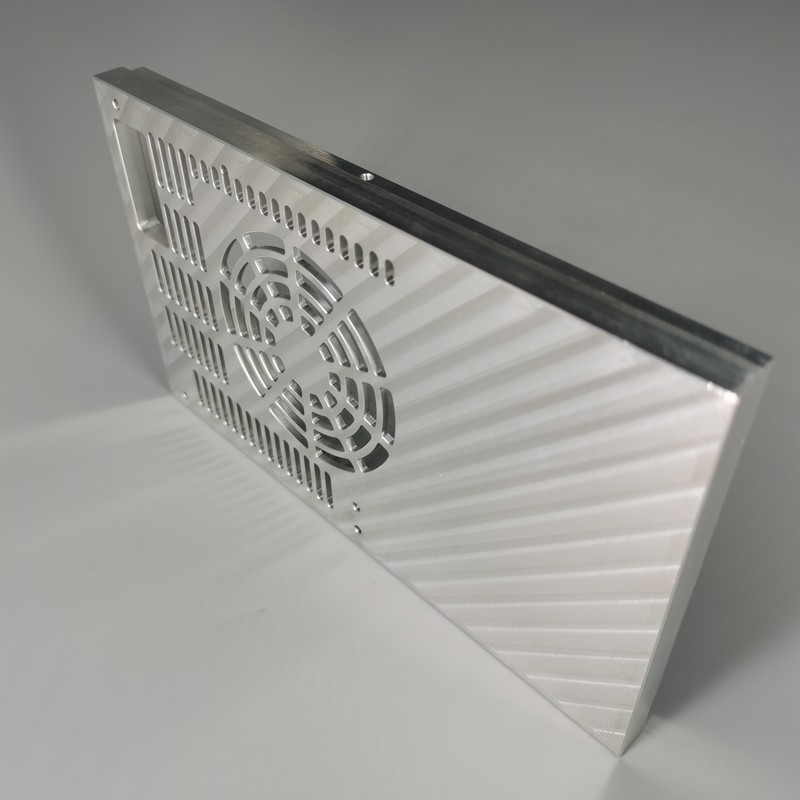

CNC Turning,CNC Milling,Laser cutting,bending,punching,

stamping machine,drilling,welding machines |

| Material: |

Steel 1214 12L14,1215

Bronze C52100,C54400,C51000

Aluminum Al6061,Al6063,AL7075,AL5052

Stainless Steel SS201,SS303,SS304,SS316

Brass C36000(C26800),C37700(HPb59),C27200(CuZn37),C28000(CuZn40)

Plastics ABS,POM,PEEK,PVC,UPVC,UHMW,Nylons,ULTEMS,PC |

| Surface finishing: |

Anodized,Oxide,Plating,Brushing,Polishing,galvanized,spraying,

High gloss polishing,Painting,Tinted,Chromed & Metallizing,Logo&Symbol,

Powder Coat,Eletrophoresis,Sandblasted&Bead blasted,

Heat treatment,Blacking. |