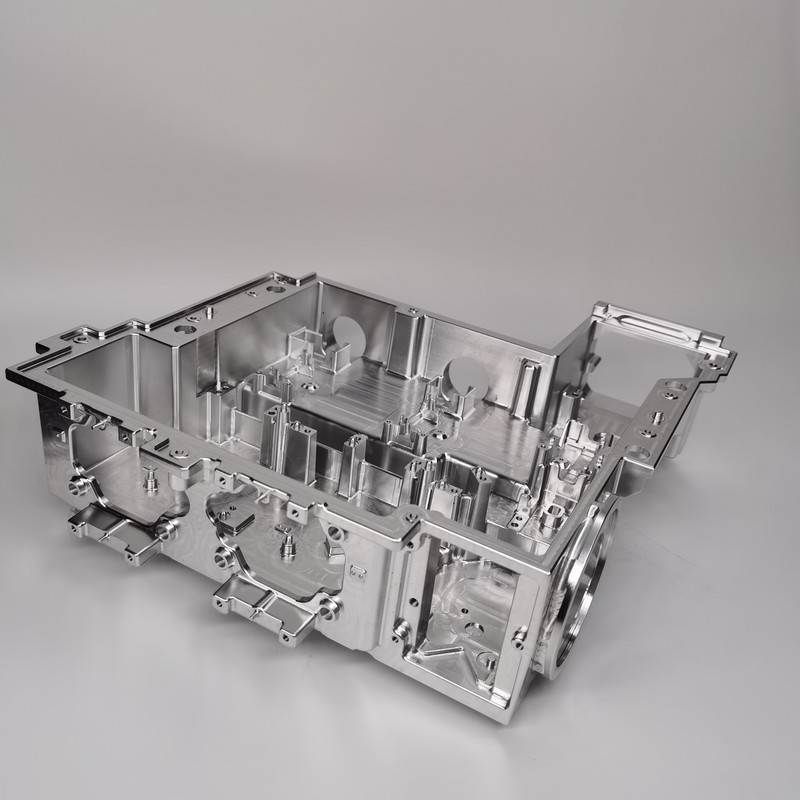

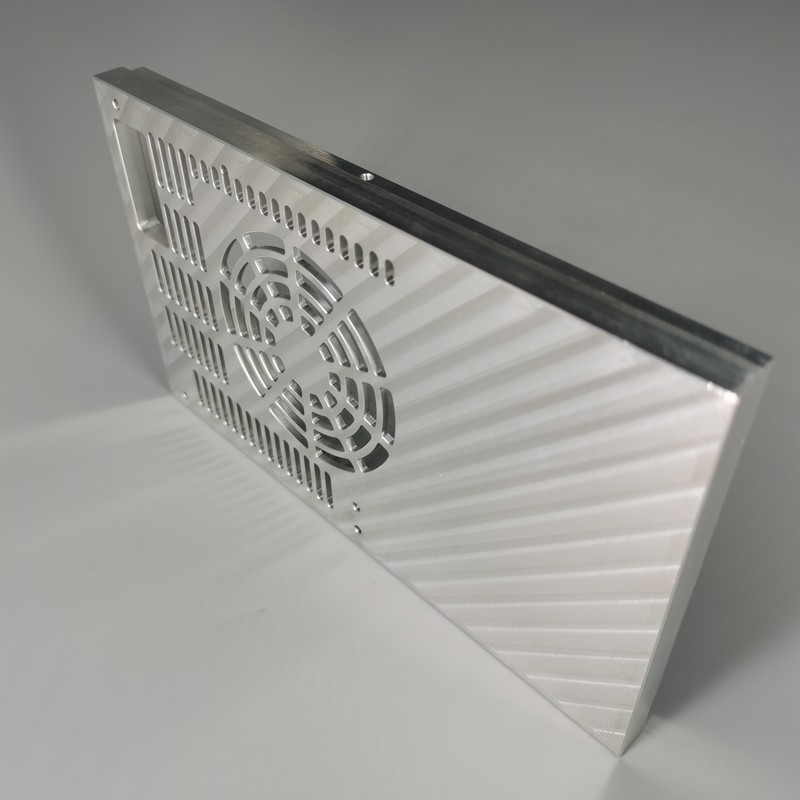

Product Features:

(1) Machining can complete the part structure that CNC can’t do, such as shaft and pipe workpiece.

(2) CNC lathe has higher processing efficiency and more advantages in cost than the ordinary lathe.

(3) After CNC machining and debugging, the quality is stable, the workpieces with high surface requirements can be in place in one step, and our qualified rate can reach 100%.

Product Parameters:

| Equipment: |

CNC Turning,CNC Milling,Laser cutting,bending,punching,

stamping machine,drilling,welding machines |

| Material: |

Steel 1214 12L14,1215

Bronze C52100,C54400,C51000

Aluminum Al6061,Al6063,AL7075,AL5052

Stainless Steel SS201,SS303,SS304,SS316

Brass C36000(C26800),C37700(HPb59),C27200(CuZn37),C28000(CuZn40) |

| Surface finishing: |

Anodized,Oxide,Plating,Brushing,Polishing,galvanized,spraying,

High gloss polishing,Painting,Tinted,Chromed & Metallizing,Logo&Symbol,

Powder Coat,Eletrophoresis,Sandblasted&Bead blasted,

Heat treatment,Blacking. |

| Inspection tools: |

Calipers,Thread Micro caliper,Projection,Pin gauge |

| Process: |

3/4/5Axis,EDM,Lathe,Line cutting, |

| File format: |

STP/STEP,IGS,X-T |

| Model Number: |

OEM |

| Certificate: |

ISO9001:2015,ROHS,SGS |

Application:

Food equipment, gas turbine parts, clock accessories, corrosion-resistant containers, equipment cavities, transmission pipelines, nitric acid-resistant equipment, tableware, thermos cups, water dispensers, non-standard automation equipment, and household appliances.